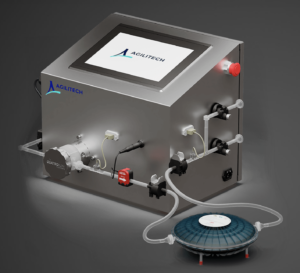

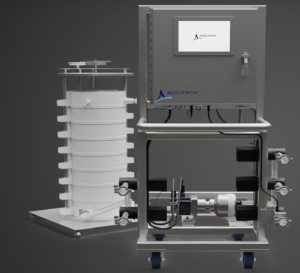

Achieving Peak Flexibility – A single-use filtration skid with multiple application capability

Current expectations for biomanufacturing require downstream systems be responsive and flexible to meet ever changing demands and requirements. A common goal is to create processes that can adapt and evolve over time to meet new needs. To address this need, Agilitech has created a multipurpose filtration system that enables a new level of flexibility. Their compact, single-use multipurpose filtration can be adapted to virtually any commercially available external filtration system and the skid design allows customers to use one skid for multiple applications – sterile filtration, depth filtration, and virus filtration. To provide for future-proof systems, Agilitech encourages customers to partner and co-design solutions that are truly fit for purpose with designs that adapt to evolving needs.

Key benefits include:

Single-use Platform

The unique skid design is completely single use. It features fully sterilized single-use tubing sets, complete with integrated sensors, to minimize the risk of contamination. Sterile-to-sterile connections for inlets and outlets also reduce contamination risks. Agilitech uses only the highest quality components assembled in a ISO9001:2015 clean rooms.

Multiple Applications

The ability of the skid to perform multiple applications, allows customers to maximize value by using it for multiple operations. For instance, the unit could be used for depth filtration, then the unit could be adapted for sterile or viral filtration, as needed. The beauty is that the multipurpose skid is not technically configured to a specific filter, they are configured to allow for depth, sterile or virus filters. Thus, the physical aspects are all the same, it is just a matter of physically connecting a different filter and configuring the parameters for the appropriate flow rate and pressure requirements of the filter. Due to their compact design, these skids can be moved to wherever they are needed in the facility.

Brand Agnostic

Another unique aspect of the Multipurpose Filtration Skid is that it is completely brand-agnostic. This means that customers are not limited to one supplier and are able to use best-in-class products and brand preferences to meet exact process requirements and optimize performance.

Automation and Control System

Customers also have complete flexibility when it comes to automation and control by choosing the platform that best fits their needs. The Multipurpose Filtration Skid can be adapted to any modern control system, including DeltaV®, Rockwell Automation®, and more. This allows company engineering teams to make modifications as needed without being locked into a specific supplier or control system.

In addition, the user experience will be the same regardless of the platform due to the ISA-88 batch-compliant structure that is used to create the building blocks of the automation. With a user-friendly control panel, functions and data most accessed by operators are brought to the top layer of the screen to save operators’ time searching for frequently accessed and/or critical information.

Scalable

Agilitech offers two options for their multipurpose filtration system, a benchtop option, and a larger skid. Both provide compact footprints that allow them to be moved around the facility and employed in different areas. Both systems are scalable and provided both systems are on the same control and design configuration, the recipes can be transferred between units with a simple change to parameter values to reflect the flow/pressure/volume of the chosen unit. For example, this allows customers to easily use the skid for depth filtration, then move the unit to another area for viral filtration.

System Operation Features

The system includes dynamic flow control, which automatically decreases flow rate should filters foul and pressure increase, thereby providing safe working conditions. It also has a volume totalizer that monitors liquid volume pumped through the system. Finally multiple inlets for product, buffer, water, and outlets for product collection or waste permit ease of operation.

Service and Support

Lastly, Agilitech provides Standard Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) documentation. Installation Qualification (IQ), and Operational Qualification (OQ) testing and documentation is also available for use in cGMP production. All systems come with a recommended preventative maintenance plan, spare parts list, and maintenance service to ensure the system operates at peak performance.