Advanced Single Use Scalable Chromatography System – Delivers 2 Flow Path Sizes in 1 Skid

The need for flexibility in bioprocessing is well documented. Changes in demand, multi-product facilities, and technology advancements are just some of the reasons bioprocessing volumes may increase or decrease. Since, it is not time or cost effective to procure, configure, and qualify new equipment to meet changing requirements, equipment that supports process flexibility is advantageous.

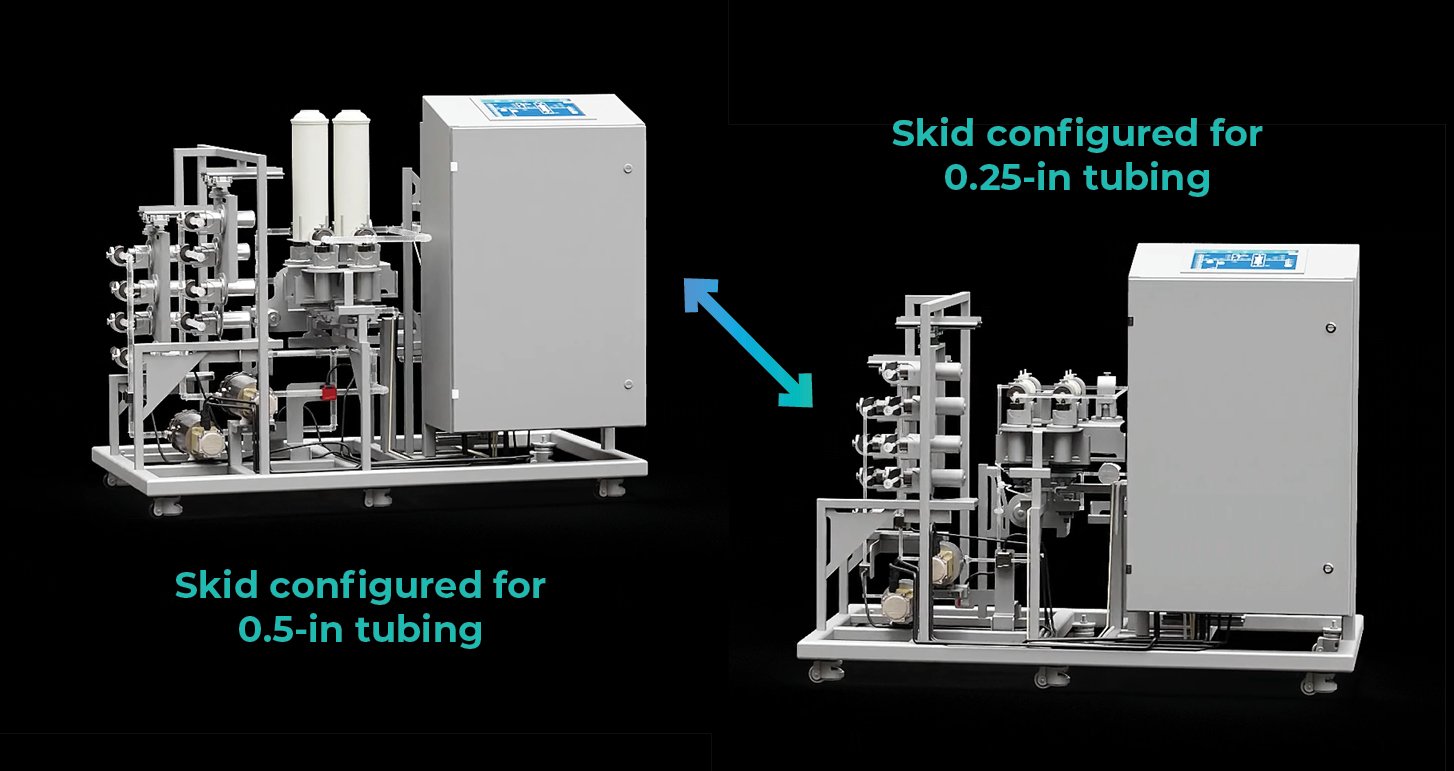

Agilitech recently launched an agile solution to enable more flexible chromatography, while still maintaining all the benefits of standard chromatography systems. Their single-use scalable chromatography system provides 2-skids-in-one. It allows users to easily scale up or down their process, or to handle different volumes within the same bioprocess using the same equipment, operations and interface. This means there is no need to re-train operators or purchase a different size skid.

The scalable chromatography system can be adapted to accommodate two different size tubing sets, transitioning between 1/4-inch and 1/2-inch tubing by simply switching out the tubing set and relevant components. This enables scale-up or scale-down of processes on site and with the company’s existing team handling the transition within 24 hours.

|

How Agilitech’s scalable chromatography skid works

This video demonstrates how the scalable chromatography skid works and the ease of switching from one scale to another. The first step to scaling the skid up or down is to change out components such as the pump receivers, valve inserts, flow sensors, bubble detectors, and the back-pressure regulator. All the components needed to configure the skid to a different size are provided in an adapter kit.

In the next step, the tubing set is exchanged. The unique scalable skid design integrates a proprietary mechanism that enables adjustment of the frame out (for a larger scale) or in (for a smaller scale). This ensures an optimal fit for the tubing, eliminating excess tubing and hold-up volume to maintain efficiency.

In the final step, parameters for the new skid configuration are changed via the control panel by selecting the tubing size from the drop-down menu. The specifications for each scale are pre-programmed. This process is the same whether scaling up from 1/4-inch to 1/2-inch tubing or scaling down.

Benefits of the scalable chromatography skid

In addition to the seamless flexibility and cost savings already discussed, benefits include:

- Brand-agnostic filters, columns, and other components enables the use of best-in-class components for every part of the skid

- Manual control to fully automated with a preferred platform

- Flexible system design with configurable flow path to meet precise requirements

- Dual inlet headers with dedicated flow sensors – deliver accurate control throughout inline dilution and gradient steps

- Outlet back pressure control valve – enables offline column pressure simulation to stabilize pumps and smooth transition to inline columns

To learn more, please view the full Scalable Chromatography System Video