Enhance Downstream Bioprocessing Efficiency with AKBA’s Award-Winning MOTIV™ Inline Buffer Formulation (IBF™) Systems

Buffer formulation is an essential part of downstream bioprocessing to produce safe and effective biopharmaceuticals more efficiently. Buffers are aqueous solutions with precise pH and ionic strength that can stabilize proteins, aid purification steps, as well as regulate enzymatic activity – and are essential to creating optimal conditions for various biochemical reactions. Specific buffer compositions are required throughout the downstream process, often in volumes that can reach thousands of liters.

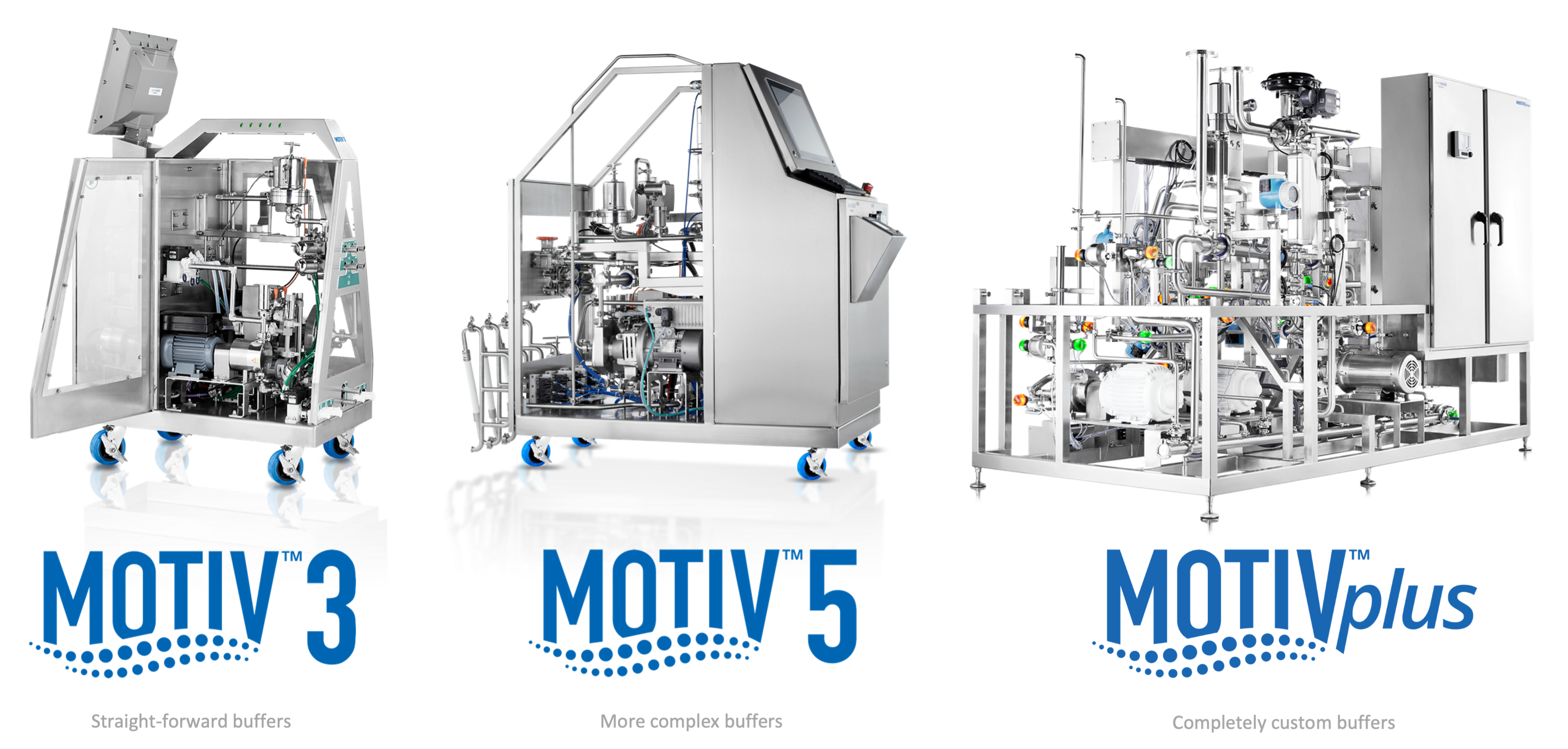

Meeting the escalating demand for therapeutic proteins and biologics requires enhanced buffer productivity. With AKBA’s award-winning MOTIV™ Inline Buffer Formulation (IBF™) Systems, you can move past downstream bottlenecks, driving buffer productivity to achieve consistent, large-scale yields with confidence. The product family includes 3-pump, 5-pump, and custom IBF configurations that can fit most any space, cost, or performance requirements.

MOTIV™ 3 is the 3-pump IBF system designed to produce dilute and conditioned buffers. The system operates by utilizing three streams, with one larger pump delivering the diluent (such as WFI or purified water) and two smaller pumps for buffer concentrate and acid/base modifiers.

MOTIV™ 5 is suitable to produce more complex buffers constructed from up to five streams. The system offers maximum flexibility for multi-component buffers using a combination of conductivity, pH, and mass flow control. It can achieve flow rates of up to 5,000 L/h encompassing a broad capacity range for process development to production scale batches.

MOTIV™plus is the ideal system for non-standard situations. From custom flow rate ranges, specific materials of construction for corrosion resistance (e.g., AL6XN), additional pumps (>5 pump systems) and inline monitors, our AKBA experts can build you a system that will do exactly what you need.

The patented Pro-Yield™ inline dynamic recirculation blender technology is built into every stainless-steel MOTIV™ and dramatically improves buffer response rate, allowing all systems to reach their target setpoints within one minute. This innovative technology offers several advantages:

- Highly efficient mixing: Regardless of flow rate or viscosity, the Pro-Yield™ technology ensures optimal mixing, promoting uniformity and consistency in buffer formulation processes.

- Increased pH adjustment precision: Enhances control over buffer composition and ensures optimal conditions for downstream processing.

- Single pass mixing: The system’s single pass mixing capability allows setpoints to be reached faster, reducing run times and minimizes washout volumes.

Learn more about MOTIV inline buffer formulation systems

Visit Asahi Kasei Bioprocess for more information

Each MOTIV™ system is also equipped with OCELOT™ System Control automation software. OCELOT offers an intuitive configuration interface for all inline buffer formulation process steps. This universally compatible software can seamlessly integrate and interface with your plant-wide control system, enabling comprehensive data collection and analysis throughout the manufacturing process.

With deep expertise installing and integrating IBF systems in facilities worldwide, our engineers will ensure that your implementation is trouble-free. Trusted globally, MOTIV IBF systems are used in cGMP production facilities, delivering cost-effective just-in-time preparation of millions of liters of dilute and pH-conditioned buffers to meet downstream bioprocessing needs.

Discover how this cutting-edge technology can revolutionize your buffer management strategy and enhance downstream processing efficiency. Click here to watch AKBA’s video to see the MOTIV systems in action: