Bioprocess International Conference – Tuesday’s Talks

Today was a great day full of interesting talks at the Bioprocess International Conference. It was difficult to choose only a few, but I have highlighted three below.

Thomas Ryll, Ph.D., Senior Director, Cell Culture Development, Biogen Idec, gave a talk titled “Impact of Single-Use Bioreactors on Upstream Processing.”

Dr. Ryll did an excellent job highlighting both the advantages of single-use bioreactors and also opportunities for improvement.

In the talk single-use bioreactor advantages were identified as:

- Requiring reduced infrastructure

- Lower capital investment

- Ease of use and labor savings

- Enables scaling down production culture volume

- Important to goals of increased globalization

Dr. Ryll also discussed how Biogen Idec implemented single-use bioreactors at their facility in Research Triangle Park after validating single-use bioreactors on a number of points and across different size bioreactors. They converted warehouse space to “gray space” where they could use single-use bioreactors at different sizes to scale up process development in a non-clinical manufacturing setting, which eased technology transfer of the perfected process to clinical manufacturing. Another interesting comparison was shared by Dr. Ryll that looked at the cost for single-use bioreactors vs. stainless steel tank bioreactors.

It was found that single-use bioreactors:

- Had higher consumables cost

- The same raw material costs

- Significantly lower utilities

- Lower labor cost

- Overall single-use bioreactors costs were found to be comparable

Dr. Ryll then pointed out the following areas as opportunities for improvement in single-use bioreactors:

- Find balance between mass transfer and bubble size

- Reduce lot to lot variability in bag lots

- Address toxic leachable from polymer films

Richard Ferraro, Business Leader WAVE Products Group, GE Healthcare, gave a technology workshop titled “Efficient and Intelligent Process Control for Animal Cell Culture.”

In the talk Mr. Ferraro discussed the high cost of drug development and possible platform and toolbox approaches to address these issues. One of the platforms covered was an intensified process approach, for example perfusion technology.

When compared with fed batch processes intensified processes have advantages, but they can also create challenges

The talk identified the following intensified process challenges:

- More training required for operation because you are working with more than just the bioreactor

- Ancillary equipment adds complexities – including connections and monitoring

- Increased logistics

- Lots more data

GE Healthcare has taken what they have learned about challenges in intensified processes and has worked to address these challenges by implementing new solutions. They have taken their comprehensive experience in downstream systems and have applied some of the same concepts to upstream. These ideas for improvements were important in the development of the new ReadyToProcess WAVE 25 Bioreactor, particularly in the area of process control.

New Tools for Process Control:

- Application specific PID parameters

- Method editor function for scheduled changes of process conditions

- Accessories to facilitate process intensification; pumps, load cells & auto-calibration function

- Intuitive user interface, help screens, set up support

- Remote monitoring – WAVE25 App

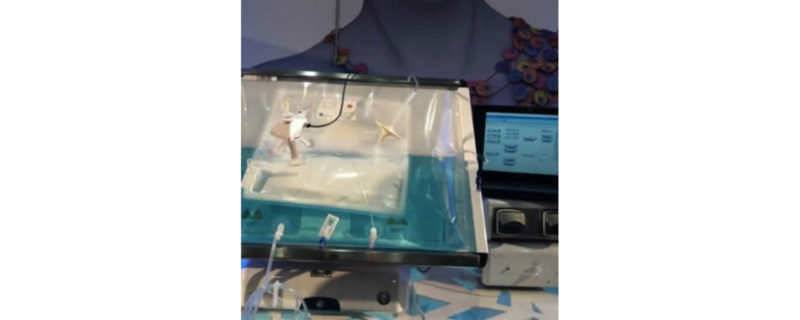

GE Healthcare launched the new ReadyToProcess WAVE 25 Bioreactor at their booth Tuesday evening, please see picture above. The new WAVE has many new and improved features and it is interesting to see the advancements after so many years of WAVE bioreactors being in use.

Sandra Poole, Senior Vice President Biologics Operations, Genzyme, gave a Keynote Presentation titled “A Systems Approach to Managing Biomanufacturing Complexity – Genzyme’s Allston Plant Case Study.”

Sandra Poole gave an excellent talk describing the challenges that Genzyme faced during their viral contamination at their Allston facility and how they have implemented a systems approach to recover and again function at capacity. I appreciated Ms. Poole’s candor and sharing a real experience as a learning tool for the industry. In the talk she discussed the importance of taking a systems approach and really looking at the ripple effect that a change in one area can have on several other areas of manufacturing. These effects often aren’t expected, but it doesn’t mean that they can’t be anticipated with careful examination. She also stressed the importance of looking at system feedback loops and determining what the limiting factor is.

Ms. Poole discusses the manufacturing competency curve and how after competency improves additional tasks are regularly added, which as a result dilutes skills. In the Genzyme example, she describes how the Allston facility was originally designed just to manufacture Cerezyme, after their capability increased, manufacturing of Fabrazyme was added and then a third product, Myozyme, was also added. These additional tasks created challenges in manufacturing and did not lend itself to a systems approach.

Since the contamination, a systems approach has been implemented and the facility is running at capacity, under consent decree at 100% batch certification. They are also implementing a work plan plus improvement program targeting their entire manufacturing system.

To close the talk, Ms. Poole described the following key learnings:

- Understanding how a change to manufacturing can impact complexity, capability and performance

- Understanding balance between a plant’s complexity and the plant’s capacity to manage that complexity

- Choosing the right tools and metrics to judge performance and health of the system are key

- Need for new skills and education in systems thinking