Lynx® CDR Connectors to Improve Sterile Fluid Transfer in Biomanufacturing

A vital part of the biomanufacturing process is being able to move fluid under sterile conditions using sterile connections. However, this activity requires considerable time and resources. One challenge is that in most cases, current disposable sterile connectors only allow users to make a single sterile connection per device, which then requires the use of multiple devices per unit operation. In addition, the flow path must be dry and non-pressurized during connection and disconnection. Due to these limitations, sterile liquid transfer can be very inefficient.

In an effort to address these issues, MilliporeSigma launched Lynx® CDR Connectors. The Lynx® CDR Connectors are multi-use disposable sterile connectors that can connect, reconnect and disconnect even when the flow path is wet and pressurized. The connectors were designed to provide high flexibility by enabling up to six connections, disconnections or reconnections of multiple flow paths per use. This provides users with a more efficient alternative to the time consuming and costly tube welding and manifold configuration traditionally used in upstream and downstream processing.

MilliporeSigma has identified several key benefits of the Lynx® CDR Connectors:

Improved Ease of Use:

The connectors are made up of three main parts -sterile housing, a male valve, and a female valve and are designed for quick and easy connections and disconnections. They are validated for up to six connections before disposal and they can also be used when the flow path is wet and pressurized.

To see how easy the Lynx® CDR Connectors are to use, please see the video below:

Enhanced Flexibility:

The Lynx® CDR Connectors can connect to different sized tubing and are available in a range of sizes from 3/8 inch hose barb to 1 1⁄2 inch TC, and configurations that include sampling, intermediate additions up to bulk liquid transfer. They also make conducting microbial sampling easier by providing a variety of sampling options. These include secure connections to enable large or small volume material transfers. Sterile connections minimize the risk of contamination and resulting false positive samples.

Better Reliability with Decreased Risk:

The Lynx® CDR Connectors provide a validated alternative to aseptic connections and thus reduce the associated risk. Secure sterile connections reduce the risk of product contamination and product leakage.

Increased Productivity and Reduced Cost:

Using the Lynx® CDR Connectors, it reduces both time consumption and overall cost. Instead of using multiple connectors/disconnectors and the need for tube welding and costly manifold configurations, MilliporeSigma offers one connector that does it all.

Case Study:

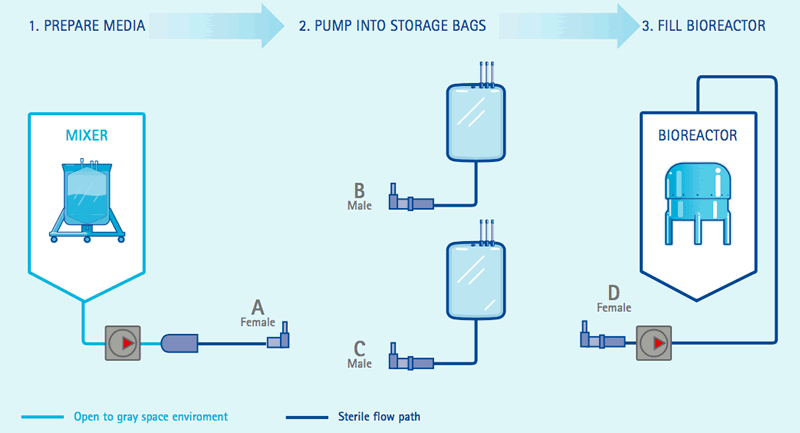

To demonstrate the efficiency of their new connectors, MilliporeSigma conducted a case study in which they utilized a typical flow path of media preparation and bioreactor fill. In this path multiple connections and disconnections were required, thereby demonstrating the efficiency in maintaining a sterile path flow even during multiple connect/disconnect/reconnect cycles. They also conducted the experiment in a non-classified “gray space” laboratory to validate the sterility of the connectors.

The experiment was conducted over 16 days, with two days for media prep, filtration and storage that was followed with a 14 day cell culture simulation in a bioreactor.

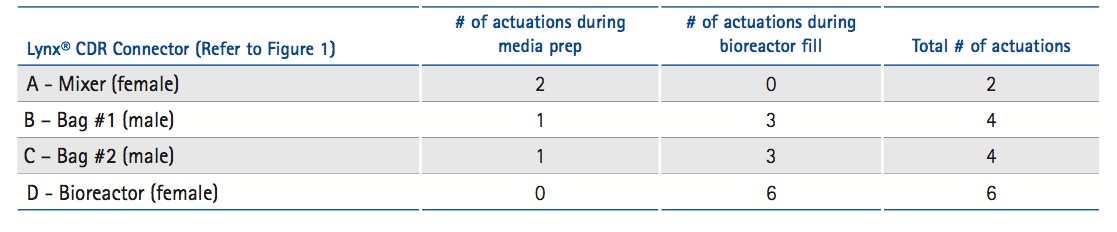

To demonstrate their multi-use, the Lynx® CDR Connectors were actuated multiple times and in multiple process steps (Table 1).

To begin the study, media was prepared in a Mobius® mixer open to the environment. Next, media was passed through a sterilizing grade filter and the Lynx® CDR Connectors were used to fill two media storage bags one stored at ambient conditions and the other stored at 2-8° C. The connectors were then used to make a total of six media additions to the experimental bioreactor culture alternating between the ambient and cold storage bags. Media additions from the cold storage bags were performed immediately after being removed from storage to show that connections can be made between the two connectors even when there are temperature differences. When not in use for additions, the connectors were left connected on the benchtop after the ambient media additions and were disconnected after the cold media additions to demonstrate that the connector could maintain a sterile flow path in either state. The experiment ended on day 16, after which, 5 liters of media were removed from the bioreactor for sterility testing to confirm no microorganism growth occurred. Media sterility testing showed that the media was negative for growth.

Conclusions

The experiment showed that the Lynx® CDR Connectors were able to maintain a sterile flow path in a “gray space” lab for a 16 day simulated cell culture run. During this experiment all of the connectors made multiple connections/disconnections with no issues and two connectors were used in multiple process steps. Successful connections were made between connector halves at different temperatures and the growth media remained sterile after processing.

For more information on Lynx CDR Connections, please see:

- Homepage: http://www.emdmillipore.com/US/en/20160227_183009?RedirectedFrom=http%3A%2F%2Femdmillipore.com%2Flynxcdr

- Mobius connectors: http://www.emdmillipore.com/US/en/products/biopharmaceutical-manufacturing/downstream-processing/single-use-manufacturing/connectors-crimping-tubing/adOb.qB.O.IAAAFDezF4saSR,nav

- Animation: https://www.youtube.com/watch?v=A1XedLg_ZjQ

- Product Demo: https://www.youtube.com/watch?v=FXihs49FDtg&spfreload=10

- Interphex 2016: https://www.youtube.com/watch?v=FXihs49FDtg&spfreload=10

- Lynx CDR Webinar: https://www.emdmillipore.com/US/en/20151116_192332?Pname=94