Utilizing High-Throughput Process Development Tools to Create a Purification Process for a Biosimilar Molecule

Biosimilar molecules have some unique manufacturing requirements that must be taken into account when planning process development. The requirements for process development typically require a good deal of selectivity, cost-efficiency and the need to meet aggressive timelines. These lend themselves to a process development approach that incorporates high throughput.

High-throughput process development

In a recent paper, “Rapid process development of a cation exchange step for a biosimilar” authors, Teichert et. al describe the use of high-throughput process development (HTPD) tools to create a purification process for a biosimilar molecule. The paper was published in the “HTPD – High Throughput Process Development,” a group of expanded abstracts covering talks presented at the fourth High-Throughput Process Development Conference in Toledo, Spain.

Authors, from both GE’s Fast Trak Services Team and Alvotech, collaborated on this project to develop a cation exchange chromatography step. GE Healthcare’s extensive downstream bioprocessing experience was coupled with Alvotech’s biosimilar expertise and knowledge around the specific requirements for their molecule to create a process that reached all purification goals.

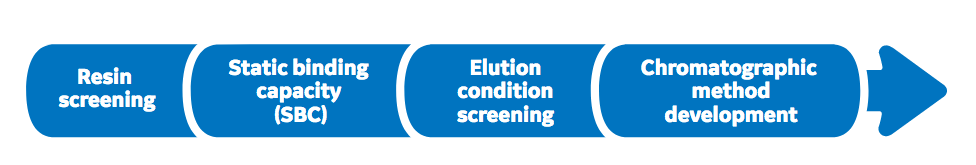

The team began by taking a standardized workflow and adapting it to a high-throughput process development approach. They screened resins from three candidates, selected based on experience. Then they optimized running conditions, again initially selected based on experience, to meet the specific biosimilar requirements. The goal was to reduce aggregate levels to approximately 0.6% after the polishing step in conjunction with obtaining the highest yield possible for the monomer. High-throughput process development experiments were performed in both 96-well plates and small-scale columns. Figure 1 provides an overview of the Fast Trak workflow used for this project.

molecule. The first part consists of screening of a wide area of conditions in a format that allows increased throughput

and provides process understanding. The final part involves development of a chromatographic method to identify

running conditions in an “easy-to-scale-up” approach.

Materials and Methods

Single resin plates were used for broad-range screening of static binding capacity for the three resins. Screening plates were used to screen elution conditions. Next column experiments were conducted on a Tricorn™ 5/100 column with a volume of 2 mL (10 cm bed height) at 5.4 min residence time, using an ÄKTA™ avant 25 system.

In the binding study, contour plots were used to evaluate static binding capacity and provided information about the binding conditions that should be tested in both the elution studies and possibly in column method screening. Next the elution screening testing provided information about yield and aggregate removal capacity. From here they were able to select the resin that was best in aggregate removal. They also looked at pH and found that lower pH was beneficial. As Capto™ S ImpAct showed the highest static binding capacity, this resin candidate and corresponding conditions were chosen for further optimization. Lastly they looked at increasing productivity by investigating dynamic binding capacity. They found that the highest binding capacity was at pH 6.0. High sample loads were also evaluated at pH 6.0. Results showed sample load of 100 g/L resin gave excellent aggregate and host cell protein removal.

By working in collaboration and sharing expertise, high throughput tools were incorporated into process development for a purification process specifically tailored to meet the needs of this biosimilar. Using the Fast Trak standardized workflow meant initial running conditions were identified in just four weeks for further process development.

I was fortunate to be able to speak to one of the authors, Kristina Nilsson-Valimaa, GE Healthcare Fast Trak Europe Leader, about the development of a purification process for a biosimilar using high-throughput process development. Below is a transcript of our interview.

What are some of the unique considerations when developing a biomanufacturing process for a biosimilar?

One of the main differences is that the goal is to match the innovator molecule in terms of product related impurities. For example, a very common challenge for biosimilars is to modify the ratio of charge variants in the biosimilar during process development to obtain the same relation as the innovator.

Why is high-throughput process development a particularly good fit for biosimilars?

Often the timelines to develop a purification process are tight for the biosimilar companies and speed to market is a key factor. Then HTPD methodology is a great fit, as it enables shorter development times compared to a common approach using small scale columns only.

In developing this process, was there anything that surprised you?

We were somewhat surprised that multimodal resins showed less efficient aggregate removal in this specific study than the other resins tested. In our experience multimodal resins are usually very efficient at aggregate removal. Learning this early on was therefore valuable, as we could focus the development on Capto S ImpAct, that displayed both the highest binding capacity and most efficient aggregate removal in this project. The HTPD studies supported us in prioritizing the column experiments on the most promising resin.

What impressed you most about the high-throughput approach?

We are working with a high-throughput methodology in most of the collaboration projects we are doing, so we have seen the benefits several times. But that we are able to develop a purification step with both high binding capacity and good selectivity in very few experiments is always highly valuable.

What advice would you have for others who are interested in utilizing high-throughput in their process development?

It is a great tool to both shorten the development times as well as learning about your molecule behavior at an early stage in the development. If used efficiently, it can speed up the development time and at the same time increase the process understanding. Also, you can utilize the HTPD results for different aspects of the development, e.g. to determine strategies to test for both binding, flowthrough and elution. For someone new to HTPD I would recommend to start by working with 96-well plates in manual mode using a plate shaker, multichannel pipette and a centrifuge. This is something common in every lab and it is a great start to learning the technology without major investments. GE Healthcare has also developed a handbook with more practical tips, which you can find here.

Please see related article:

- High Throughput Process Development in Biomanufacturing – Current Challenges and Benefits

- Implementing Digital Biomanufacturing in Process Development