Monolithic Chromatography Enables Process Intensification of Virus Purification

Monolithic Chromatography

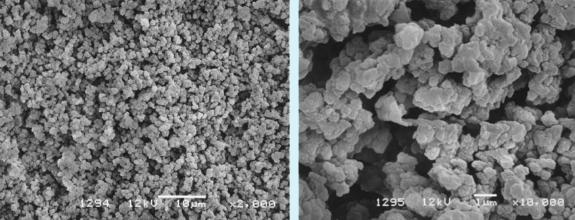

Monoliths are unique from other forms of chromatography media for several reasons. Monolith architecture consists of highly interconnected convective channels that are distributed throughout the entire bed. The large channels are easily available for purification even for large biomolecules. This unique architecture also creates a void-less space, thus significantly reducing shear and product loss. In monoliths, the mass transport is also exclusively convective and laminar which means that all solutes flow with the current regardless of size and require only a few seconds of residence time.

These features make monoliths well suited for the purification of large biomolecules, such as virus particles, vesicles, proteins, RNAs, plasmids and other forms of DNA. Large biomolecules, such as viruses, can be vulnerable during purifications in ways that smaller biomolecules, for example antibodies, are not. For instance, their large size makes them more vulnerable to shear stress and slow diffusion constants. This results in slower process speeds, low capacities and reduced recovery rates when purified with traditional chromatography media.

Monoliths for Virus Purification

Monoliths are a particularly good fit for virus purification for a few key reasons:

Monoliths are a particularly good fit for virus purification for a few key reasons:

Low Shear Stress

Viruses are sensitive to shear stress, especially lipid envelope viruses, where the envelope can be stripped due to shear. Shear also contributes to low virus recovery rates. Since the flow through on monoliths is laminar with no formation of eddies or void spaces, there is very little turbulent shear stress.

High Recovery Rates

Monoliths also feature channels that are highly interconnected, which means that there are no dead ends. This, along with the lack of turbulent shear, has been shown to deliver higher virus recovery than other chromatography formats.

Increased Flow Rate

Viruses have slow diffusion constants, which makes traditional chromatography purification slow. The convective flow provided by monolithic channels is good for viruses because binding efficiency and elution kinetics are not negatively impacted by large product size. There are no restrictions on flow rate based on product size either and because of the monolith architecture, no additional shear stress even at high flow rates. This allows monoliths to be run at flow rates significantly higher than on porous particle columns with no loss of performance. For example, the dynamic binding capacity for influenza virus on monoliths has been shown to be 10-100 times higher than with porous particle columns (see case study).

Monolith Chromatography Enables Process Intensification of Influenza Virus Purification

Process intensification is a manufacturing strategy being implemented across biomanufacturing. Process intensification involves combining process steps to reduce manufacturing time, improve efficiency and increase reproducibility.

In a recent case study “Intensification of Influenza Virus Purification” published this month in BioProcess International, authors describe a highly intensified influenza virus purification strategy using monoliths. In the study, authors developed a scalable process for purification of Influenza A and B produced in Vero cells, as well as a scale down version for process development and process control documentation.

Authors point out that monolithic chromatography is a perfect fit for purifying lipid-envelope viruses including Influenza A and B due to the negative impact that shear stress can have stripping the envelope.

In the intensified influenza purification process, authors were able to remove the TFF steps and replace them with a single chromatography step using a single-use cation-exchange monolith. By carefully selecting process buffers they were able to achieve final formulation with a simple dilution of the product pool. By concentrating and purifying at the same time they were able to cut several process steps and also remove well-documented sources of shear stress. Results showed that they were able to achieve DNA digestion in two hours, capture purification and formulation within four hours with host-cell protein and DNA reduced more than 99% and final virus recovery at 80%.

The authors point out that of course not all purification can be done with just a couple chromatography steps, but the same principles can be applied with similar opportunities for increasing process intensification.

The unique advantages monoliths provide including low shear, rapid flow rate and high recovery rates provide a good fit for virus purification and several opportunities for process simplification and intensification. In addition permit process simplification and intensification of virus purification.

Expert Interview

We were fortunate to be able to speak one of the authors of the study, Mojca Tajnik Sbaizero, Product Manager, BIA Separations about the use of monoliths and influenza virus purification. The transcript of our interview is included below.

In working on this Influenza project was there anything that surprised you about the process? What was the most exciting aspect of the process intensification you achieved?

What surprised me the most was the actual column capacity. We were able to purify tens of liters of material with a small-sized, few mL monolith. All this was done with material that was not even filtered but low-speed centrifuged. Our monoliths can be reffered as smart filters, and this is the base of our process intensification. We noticed that just the dilution is enough to achieve binding of the virus to the cation exchanger. This was probably the most exciting moment when we observed that Influenza has much stronger affinity to the cation exchanger than high majority of contaminants. This helped us to obtain very simple formulation, just with simple salt concentration and buffer capacity adjustment using dilution strategy. Real value of this process is in simplicity. And simplicity means intensification.

In the study you focused on Influenza viruses, could you tell me about the use of monoliths on other viruses?

Our technology is used for more than 100 pre-clinical and clinical projects involving viruses. So far we did not work with viral projects where monoliths were not being beneficial. In principle, larger or more sensitive is the virus, bigger is the advantage of the monoliths. Our range of monolith products is very wide and it can be adapted to specific needs of any virus, as well as contaminants present in the starting material. Because of large channel sizes and no shear stress while operating, monoliths are ideal tool for viral purification.

This case study is directed to vaccine manufacturing, what about gene therapy manufacturing? Can similar improvements be achieved with viral vector manufacturing?

High titer, high potency and high purity,are the main focus for efficient downstream purification to generate clinical product used for gene therapy. Here use of monoliths is undoubtful. Due to much higher titer per dose needed larger column sizes are used for viral vector capture step. For example, we developed platform process for adeno associated viral purification, that similar to the presented case, omit the use of TFF. Also, we separate empty from full capsids in the product and intensify the process with high purity and fast operation time. Similar is valid for other viral vectors, such as adenoviruses and others.

How do you think downstream processes can be further intensified?

We would like to intensify processes also for other viral vaccines and vectors in this direction as for the influenza process: the least steps as possible and high productivity. In my opinion stronger connection with the upstream processing can even further intensify the purification. One such example would be continuous chromatography. Together with process analytics we could more precisely define optimal stop of the production to minimize the input of the impurities and increase purification intake.

How do you see monoliths fitting into the future of downstream purification?

I think monoliths are the future of downstream processing of large biomolecules. In the near future, this will be especially important with the growing demand of gene therapy products of higher purity, vaccine manufacturing and large vesicles purification.

In this article we focused on large biomolecule purification, specifically viruses, but how do monoliths fit into other biomolecule purification processes?

Monoliths can be used for any biomolecule purification. Like for viruses, our technology is also highly suitable for nucleic acid purification, such as plasmid DNA, RNA molecules, as well as complex cell vesicles and other large biomolecules.

How do you scale monoliths from lab to commercial scale?

Scaling up of chromatographic processes from laboratory or process development scale to pilot and manufacturing scale is an important and challenging task and has been dealt with several strategies. When working with monoliths scaling up is a simple. The reason for this are flow independent capacity and resolution. Moreover, radial format enables short chromatographic path, high porosity results in low pressure drop with linear connection to the flowrate. Short bed height is allowing high flow rates even at production scale. In process development we are using either iso-resolution scale up with implementing simple equation when there is high variability between scale-up flowrates. Another option is scaling on a volume basis with constant flowrate. The defining factor is the chosen operating flow rate at the largest scale. With this approach we scale-up processes from small lab scale size to big production lots. Currently several of our processes are succefsully running at full production scale.

For more details about the study, including materials and methods and full results, please see “Intensification of Influenza Virus Purification”

https://bioprocessintl.com/downstream-processing/chromatography/intensification-of-influenza-virus-purification-from-clarified-harvest-to-formulated-product-in-a-single-shift/

For more information about monolithic chromatography, please see

https://www.biaseparations.com/en/technology

About the Interviewee:

Mojca Tajnik Sbaizero, PhD, Product Manager, BIA Separations

Mojca Tajnik Sbaizero, PhD, Product Manager, BIA Separations

Mojca is a project manager at BIA Separations, Slovenia. She is a biotechnologist and received her PhD in 2013 in the field of genetics. Later she worked on academic level in the field of gene therapy, developing new therapeutic strategies for hereditary disorders. She joined BIA Separations in 2016 and since then works in downstream processing involving viral products.